d-type pellet mill

This D type model pellet machine belongs to small pellet mill machines because of its small capacity: 60-400kg/h. As a result, it is more suitable for home use or commercial use for farms and small plants.

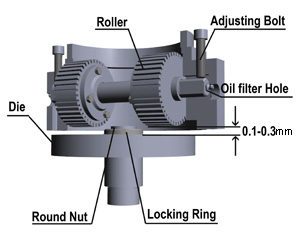

It is a flat die pellet machine: the roller is fixed on the upper body of the pellet mill, and the flat die is rotating with the main shaft.

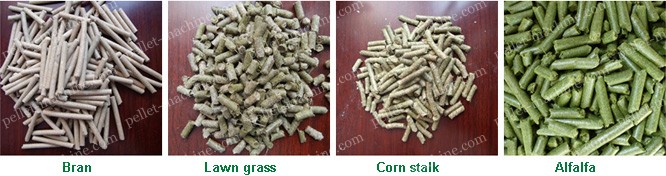

Raw materials for biomass pellet machine

The pellet machines in this series are with high adaptability to process soft wood/biomass materials, such as agricultural biomass waste (corn cobs & stalks, rice straw, cotton straw, rice husk, peanut shell, bamboo powder, hemp fiber, waste paper, grass, sunflower husk, etc.) or soft wood (pine, fir, cypress, larch, basswood, etc), so it is known as biomass pellet machine.

The D-type biomass pellet machine can make soft wood or biomass pellets in 4, 6, 8, 10mm diameter.

Biomass pellet machine technical parameter

Normal type

|

Model Number | Power(kw) | Output(kg/h) | N.W./G.W.(kg) | Package Size(mm) |

|---|---|---|---|---|---|

| ZLSP150B | 3phase, 5.5 | 50-100 | 95/100 | 800*450*700 | |

| ZLSP200B | 3phase, 7.5 | 80-120 | 200/230 | 1050*480*930 | |

| ZLSP230B | 3phase, 11 | 120-200 | 290/320 | 1180*540*1000 | |

| ZLSP260B | 3phase, 15 | 160-250 | 320/360 | 1240*540*950 | |

| ZLSP300B | 3phase, 22 | 250-400 | 350/380 | 1300*560*1100 |

With fully covered electric motor

|

Model Number | Power(kw) | Output(kg/h) | N.W./G.W.(kg) | Package Size(mm) |

|---|---|---|---|---|---|

| ZLSP150C | 3phase, 5.5 | 60-110 | 105/125 | 1000*480*780 | |

| ZLSP200C | 3phase, 7.5 | 80-120 | 210/230 | 1050*550*830 | |

| ZLSP230C | 3phase, 11 | 120-200 | 290/320 | 1200*560*950 | |

| ZLSP260C | 3phase, 15 | 160-250 | 340/370 | 1240*580*1000 | |

| ZLSP300C | 3phase, 22 | 250-400 | 425/465 | 1300*620*1100 |

See an operation video of pine sawdust pellets making

Advantages of small biomass pellet machine

As one of the Hot Sale pellet mills, D-type flat die biomass pellet machine have many advantages:

As one of the Hot Sale pellet mills, D-type flat die biomass pellet machine have many advantages:- The operation is very easy, one man can handle everything. What you need to do is to prepare the material according to our instruction and do have enough space for the pellet storage.

- Our biomass pellet machine is with CE motor, ensuring the stable power supply.

- The key part of the biomass pellet machine is the roller and die. The quality of the metal and related treatments will influence the service life and wear-resisting significantly. We choose high quality industry standard 40Cr alloy steel and treat them by vacuum heat case hardening process.

Various biomass pellets

GEMCO biomass pellet machine, your best choice!

As one of the world leading pellet machine manufacturers, GEMCO offer you high quality biomass pellet machine with all-round service. You will get the one that rightly suit your local voltage and frequency. Besides, GEMCO biomass pellet machine also has durable spare parts, so that you can use them longer.

If you are interested in our biomass pellet mill machine, just feel free to contact us!

If you have not determined which one to choose, just consult us! Our professional sales team will give you most helpful advice!